PE80 PIPE Specifications

PE80 PIPE Produced in Abrah Dashte Markazi Company are in Class of PE80 polyethylene high-density (PE-HD) pipes and have 2 base model depend on raw material as PE80 Pipe Black and PE80 Pipe Masterbatch which is produced with best 100 % Virgin polyethylene material from the top Qualified petrochemical Companys in the middle east and Europe in different Pressure Nominal (PN) 20 bar - 16 bar - 10 bar - 12.5 bar - 8 bar - 6 bar - 5 bar - 4 bar and Standard Dimensions ratio (SDR) 33, 26, 22, 21, 17.6,17, 13.6, 11,9, 7.4, for different applications of Polyethylene pipe as HDPE Pipe for potable water, HDPE Sewer Pipe, HDPE Pipe in Industrial Application, HDPE Pipe for Mining Applications, HDPE Pipe in power plant, HDPE Pipe conduit, HDPE PIPE in shipbuilding and much more like irrigation and manufacture base on international standards DIN 8074, ISIRI 14427, ASTM F714, DIN EN 12201,

PE80 PIPE advantages

PE80 pipes have a long history of fulfilling needs in fields of Potable water, Sewer main force, HDPE conduit, M&I, Mining applications, and PE80 pipes are still usable in a wide range of applications.

Difference between HDPE PE80 and PE100

PE80 pipes have a Higher price in front of PE100 pipes because they have higher wall thickness so they have a higher weight in each meter in front of PE100 PIPE. PE80 materials are the previous generation or the second generation of Polyethylene material and with the development of the 3rd generation of Polyethylene material (PE100) in most of the cases have been replaced with PE100 Materials. lower Density of PE80 pipe cause this pipe has nice flexibility and better installation results.

PE80 PIPE design specifications

PE80 PIPE known with MRS 8.0 or minimum strength required 8.0 megapascal (Mpa) and HDS 6.3 or hydrostatic design basis 6.3 megapascal (Mpa) in the Abrah Dashte Markazi's Engineering manuals for polyethylene (PE) piping systems.

PE80 Means

The polyethylene material types are classified according to their minimum strength, their minimum resistance to stress, at 20°C over a time period of 50 years. This strength is classified in MRS: minimum required strength (Mpa). MRS represents the long-term circumferential stress in the pipe where the break may occur after 50 years at the earliest. the MRS value, multiplied by 10 is the “classification” of the material. As an example, materials with an MRS of 8.0 Mpa and are therefore classified as PE80 pipes.

PE80 DATASHEET

![]() HDPE PIPE Catalogue Engineering manual for polyethylene Piping systems

HDPE PIPE Catalogue Engineering manual for polyethylene Piping systems

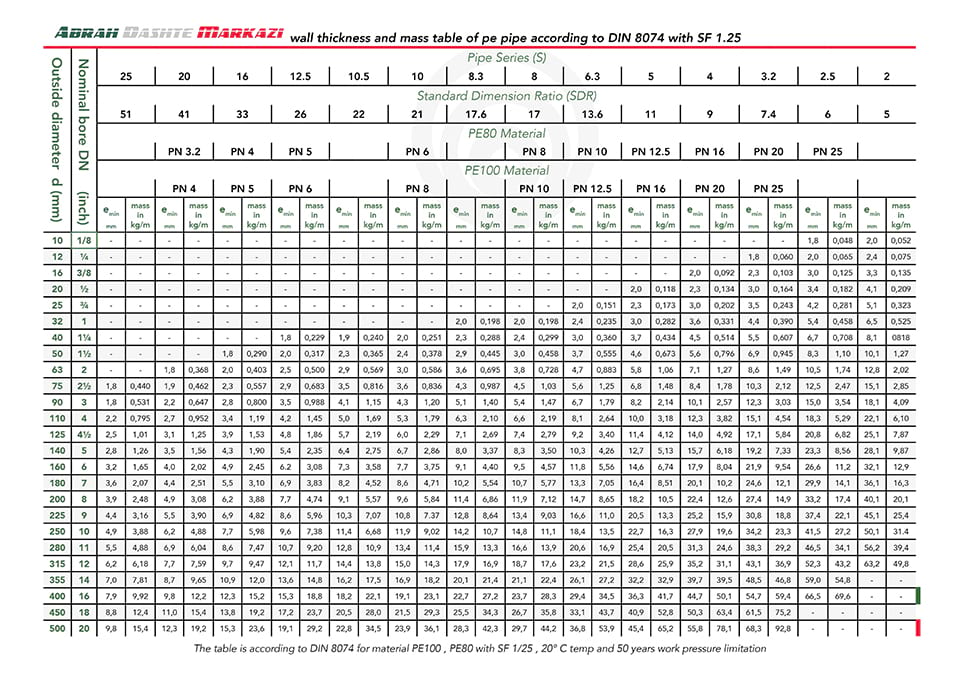

![]() wall thickness and mass table of pe pipe according to DIN 8074 with SF 1.25

wall thickness and mass table of pe pipe according to DIN 8074 with SF 1.25

![]() Allowable working pressure for pipes conveying water, with a safety factor of 1.25

Allowable working pressure for pipes conveying water, with a safety factor of 1.25

![]() Allowable working pressure for pipes conveying water, with a safety factor of 1.6

Allowable working pressure for pipes conveying water, with a safety factor of 1.6

![]() Allowable working pressure for pipes conveying water, with a safety factor of 2

Allowable working pressure for pipes conveying water, with a safety factor of 2